18 |

THIELE

Chain Company

|

Drop Forging

Chain Size

d x t [mm]

Article No. Test Force

kN

Elongation

under test force

% max.

Breaking Force

kN min.

Elongation at

fracture

%

Minimum

Defection

[mm]

18 x 64

F13209

320

1,6

510

12

18

19 x 64,5

F13314

360

1,6

570

12

19

22 x 86

F13405

480

1,6

760

12

22

24 x 87,5

F13459

570

1,6

900

12

24

26 x 92

F13518

670

1,6

1060

12

26

30 x 108

F13660

890

1,6

1.410

12

30

34 x 126

F13804

1.140

1,6

1.820

12

34

38 x 137

F15091

1.430

1,6

2.270

12

38

THIELE Rock Quality (TRQ) TWN 0108

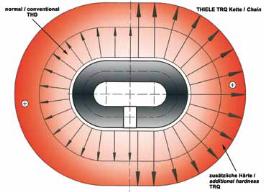

THIELE Rock Quality Chains (TRQ) were specially developed for the conveying of abrasive materials in

stone drifts and roadway drivages. Careful tempering ensures hardness levels of 420 - 450 HB

(1440 - 1540 MPa) over the entire cross-section of the material and a uniform surface hardness at any

point on the chain link.

The TRQ Chain also exhibits a high tensile strength with a fracture stress of 1000 N/mm². The combination

of tensile strength and hardness opens up opportunities for use in diffcult conveying situations where high

tensile loads would rule out the use of surface hardened chains.

TRQ Chains can be operated up to a maximum speed of 0.5 m/s, as the frictional heat generated at

higher chain speeds would result in hardening of the shanks and lead to dangerous crack formation.

the above values apply to chains in ‘natural black’ condition (NSW)

Strength: 420 - 450 HB10

For conversion HB10 to MPa see page 15