16 |

THIELE

Chain Company

|

Drop Forging

Chain Size

d x t [mm]

Article No. Test Force

kN

Elongation

under test force

% max.

Breaking Force

kN min.

Elongation at

fracture

%

Minimum

Defection

[mm]

22 x 86

F13394

456

1,4

670

18

22

26 x 92

F13506

637

1,4

940

18

26

30 x 108

F13646

848

1,4

1.250

18

30

34 x 126

F13872

1.090

1,4

1.610

18

34

38 x 137

F15090

1.360

1,4

2.010

18

38

42 x 137

F15095

1.660

1,6

2.220

14

42

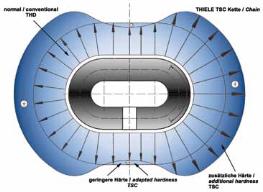

THIELE Super Crown (TSC) TWN 0100

THIELE developed the TSC series of Round Link Chains with wear-resistant crowns (THIELE Super Crown)

in order to reduce link wear on plough chains and increase chain operating life.

As frictional heat in the fast running plough chains (which travel at over 3.0 m/s) leads to hardening of the

legs and to dangerous crack formation the material strength of the legs is deliberately reduced by secon-

dary heat treatment – thereby increasing the crack arrest capacity.

THIELE TSC chains are widely used on chain scraper conveyors because of the increased hardness of

their joints. This extra hardness rating inevitably means that the chains are more susceptible to stress

corrosion cracking and so TSC Chains are not recommended for corrosive environments – especially when

ftted to face conveyors.

the above values apply to chains in ‘natural black’ condition (NSW)

Strength:

Crown 378 – 413 HB10;

Leg 342 – 371 HB10

For conversion HB10 to MPa see page 15

Picture: RAG