| 15

Chain Company

|

Drop Forging

THIELE

Chain Size

d x t [mm]

Article No. Test Force

kN

Elongation

under test force

% max.

Breaking Force

kN min.

Elongation at

fracture

%

Minimum

Defection

[mm]

14 x 50

F13101

185

1,6

246

14

14

18 x 64

F13206

305

1,6

407

14

18

19 x 64,5 F13311

340

1,6

454

14

19

22 x 86

F13401

456

1,6

608

14

22

24 x 86

F13482

543

1,6

724

14

24

24 x 87,5

F13456

543

1,6

724

14

24

26 x 92

F13513

637

1,6

850

14

26

30 x 108

F13653

848

1,6

1.130

14

30

34 x 126

F13813

1.090

1,6

1.450

14

34

38 x 137

F13877

1.360

1,6

1.820

14

38

42 x 137

F15093

1.660

1,6

2.220

14

42

Mechanical Properties

(THD)

the above values apply to chains in ‘natural black’ condition (NSW)

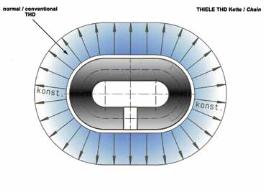

THIELE round-link chains can be used on both face conveyors and stage loaders and are also suitable as

traction elements for coal ploughs. To ensure that its products can meet the tough demands of today’s

mining industry THIELE has developed its own chain steels based on many years of manufacturing know-

how.

Each production stage is accompanied by careful and thorough quality control tests. THIELE chains are re-

cognised the world over for their performance and durability.

This is why THD round-link steel chains are hardened and tempered to a strength of 342 – 371 HB10

(which applies uniformly over the entire link). For chains intended for face conveyors this strength level

represents the optimum in terms of impact resistance (notch impact strength) and wear resistance (hardness).

THIELE Heavy Duty (THD) DIN 22252-2

Important for converting hardness

measurements into tensile strength:

The strength specifcation of all THIELE chains

is based on hardness measurements according

to the Brinell scale.

Converting hardness measurements into tensile

strength [MPa] has until now been carried out

using Table A1 in DIN EN ISO 18265. The new

DIN 22252 / 22255 however has changed over

to Table B2.

Applying Table B2 produces a different set of

tensile strengths from those of Table A1.

Strength: 342 – 371 HB10