| 9

Chain Company

|

Drop Forging

THIELE

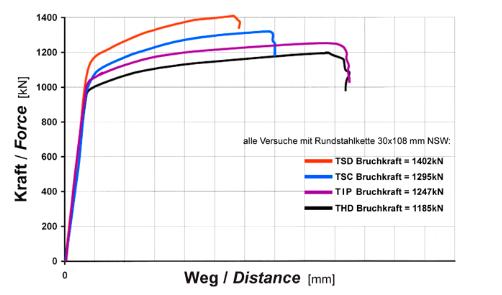

Breaking-strength comparison for THIELE chain grades

In the elastic range (up to the testing force) all chains exhibit the same characteristic because their elastic

elongation is determined by their geometry alone.

Plastic (permanent) deformation only sets in when the load applied begins to exceed the testing force.

Because of the higher hardness levels of TSC and TSD Chains correspondingly higher forces are needed

to produce plastic deformation here.

Whatever the steel, increasing hardness naturally goes hand in hand with a reduction in the ultimate elonga-

tion or deformability of the material. This means that TSC and TSD Chains exhibit lower levels of elongation

at break.

By using a special grade (TIP) of mining chain steel THIELE is able to increase the breaking force, hardness

and wear resistance by approx. 5% while retaining the chain’s impact strength and deformability.

For TIP Chains the testing forces and breaking forces are therefore some 5% higher with no loss in ultimate

elongation.

All tests based on a 30x108 mm ‘natural black’ Round Link Chain.

TSD Breaking Force = 1402 kN

TSC Breaking Force = 1295 kN

TIP Breaking Force = 1247 kN

THD Breaking Force = 1185 kN