10 |

THIELE

Chain Company

|

Drop Forging

THIELE corrosion protection

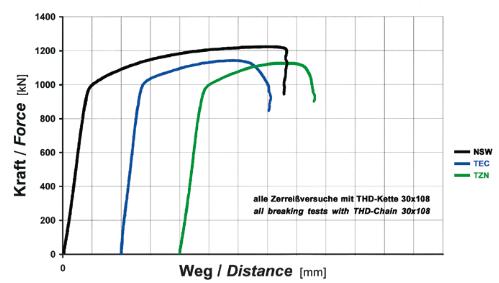

The chain breaking forces given in the relevant standards and catalogues refer to tensile tests on a ‘natural black’

chain surface of the type produced after heat treatment. This surface is covered with scale and typically exhibits

a high degree of roughness and a high frictional resistance.

Each corrosion layer, whether Tectyl, Corostar or zinc, reduces the breaking force of the THD chains by up to 10%

and the ultimate elongation by as much as 20% when compared with the catalogue values (see also DIN 22252

and DIN 22255). The frst contact with the conveyed product also produces the same result.

The application of an anti-corrosion layer does not however affect the quality or functionality of mining grade

chains. It merely reduces the frictional resistance at the chain-link pivot points and the resulting breaking force and

ultimate elongation values. The relevant chain-quality values, namely testing force, test elongation and operating

force, along with the material strength, remain unchanged.

THIELE offers the following corrosion protection options to meet different underground conditions and storage

times:

a) Tectyl dipping (TEC) – for short storage times and favourable conditions (page 11)

b) Corostar Plus (COR) – for medium storage times and particularly as ‘running in’ protection for plough chains (page 11)

c) Hot-dip galvanising (TZN) – for longer storage periods or corrosive operating conditions (page 12)

For technical reasons (see DIN 22252) fnal testing is carried out before the corrosion protection is applied. The

breaking force and ultimate elongation values therefore apply to the chain in its ‘natural black’ condition. Hot-dip

galvanised chains are an exception in that they are again tested after galvanising.