22 |

THIELE

Chain Company

|

Drop Forging

Chain Size

d x t [mm]

Article No. Test Force

kN

Elongation

under test force

% max.

Breaking Force

kN min.

Elongation at

fracture

%

Minimum

Defection

[mm]

26 x 92

F14965

637

1,6

850

11

26

30 x 108

F13771

848

1,6

1.130

11

30

34 x 126

F13807

1.090

1,6

1.450

11

34

38 x 126

F15051

1.360

1,6

1.820

11

38

38 x 137

F13891

1.360

1,6

1.820

11

38

38 x 146

F15076

1.360

1,6

1.820

11

38

42 x 146

F15041

1.660

1,6

2.220

11

42

48 x 144/160 F14953

1.850

1,6

2.900

12

48

48 x 152

F14964

2.170

1,6

2.900

11

48

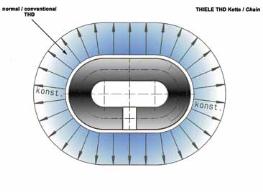

THD Flat Type Chains TWN 0102/1

Most of the world’s face conveyors now use Flat

Type/DUALINK

®

Chains from the THD range.

the above values apply to chains in ‘natural black’ condition (NSW)

THD DUALINK

®

-Chains

Chain Size

d x t [mm]

Article No. Test Force

kN

Elongation

under test force

% max.

Breaking Force

kN min.

Elongation at

fracture

%

Minimum

Defection

[mm]

24 x 86

F13484

543

1,6

724

11

24

30 x 108

F13666

848

1,6

1.130

11

30

38 x 137

F13918

1.360

1,6

1.820

11

38

42 x 146

F15021

1.660

1,6

2.220

11

42

48 x 152

F14956

2.170

1,6

2.900

11

48

52 x 170

F14974

2.550

1,6

3.400

11

52

56 x 187

F14975

2.960

1,6

3.950

11

56

60 x 189

F14976

3.390

1,6

4.520

11

60

the above values apply to chains in ‘natural black’ condition (NSW)

THIELE offers the following types of corrosion

protection for THD Flat Type/DUALINK

®

Chains,

depending on underground conditions and storage

times:

a) Tectyl dipped (TEC) – for short storage times and

good conditions (page 11)

b) Hot-dip galvanised (TZN) – for longer storage

times and corrosive operating conditions (page 12)

Strength: 342 – 371 HB10

For conversion HB10 to MPa see page 15